- Home

- News

- Researchers

- 2020

- Provision of face shields to the Keio University Hospital

News

About the project

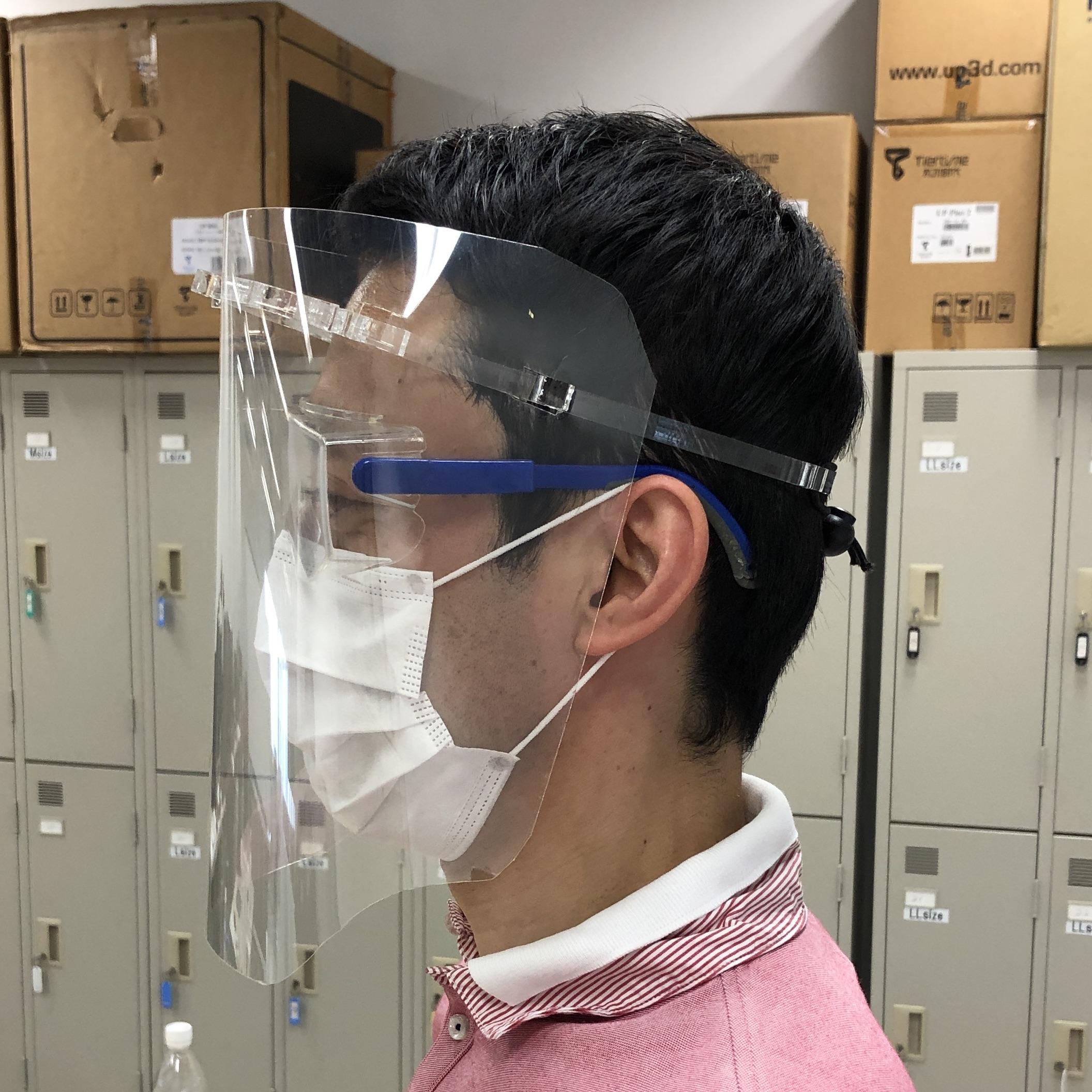

The Keio University Faculty of Science and Technology used a laser processing machine at Yagami Campus for the urgent manufacture of face shields, which were provided to the Keio University Hospital. There has been a rapid increase worldwide in the demand of protective equipment due to the COVID-19 (coronavirus disease) pandemic, making the supply of these products unstable. Faculty members promoting collaborative research between engineering and medicine at the university shared information regarding protective equipment, leading Professor Kenjiro Takemura, Associate Professor Genya Ishigami, and Professor Norihisa Miki of the Department of Mechanical Engineering as well as graduate students at the Ishigami Laboratory to design and manufacture face shields in a short period of time. These were delivered to the Keio University Hospital on May 18. Through activities like this, the Keio University Faculty of Science and Technology is helping to maintain a stable medical care system.

Two types of face shields were provided: a frame version made of an acrylic frame and PET film, and a simple version simply cut from a PET sheet that is extremely easy to assemble. Both were designed to be produced in a relatively short period of time during emergencies, and were manufactured using a laser processing machine for the cutting procedure.

Frame version of face shield

Frame version of face shield

Simple version of face shield

Simple version of face shield

Production and supply timeline for the Keio face shield

|

Date |

Details |

|---|---|

|

April 27 |

Information on the supply status of protective equipment is shared, work begins online on the same day |

|

April 30 |

Design completed |

|

Golden week |

Material procurement |

|

May 12 |

Prototype, feedback from doctors |

|

May 14 |

Manufacturing process finalized |

|

May 18 |

100 sets manufactured, delivery to the Keio University Hospital |

A web-based collaboration hub was used to share information during the development process, and in addition, 4 web meetings were held. After spending 3 days on prototyping and manufacturing, the products were delivered. As the campus was closed due to COVID-19, the production was carried out with special permission in the minimum number of days with the smallest number of people (faculty members only; graduate students provided support online) while measures were taken to prevent infection.

Project members