- Home

- New Kyurizukai

- Computational Solid Mechanics and Information Technology from Keio's Faculty of Science and Technology

Computational Solid Mechanics and Information Technology from Keio's Faculty of Science and Technology What is the Future of Computer Aided Engineering?

Passing the baton of my love for computational mechanics to the next generation!

Ever since Mayu Muramatsu learned about the laws of motion in high school, she has had an insatiable enthusiasm for learning about mechanics. As she continues her work in computational mechanics*, Muramatsu is constantly working to invest her energy in nurturing future generations and making progress towards new discoveries in the study of mechanics so that it continues to be a societally relevant academic field of knowledge.

*Computational mechanics is a field of study in which mechanics are understood through computer simulations rather than physical experiments.

Mayu Muramatsu

Mayu Muramatsu’s academic specialties are in computational mechanics, solid mechanics, and materials engineering. In 2007, she graduated from the Keio University’s Department of Mechanical Engineering in the Faculty of Science and Technology. She then completed her doctoral degree (engineering) in 2011 working in the Shizawa Laboratory which is overseen by Dr. Kazuyuki Shizawa, Department of Mechanical Engineering, Faculty of Science and Technology, Keio University. After working as an assistant professor for the Ohmura Laboratory in this same department, in 2012 she became a project researcher for the Institute of Advanced Industrial Science and Technology (AIST). In 2014, she began working as an assistant professor at Tohoku University. In April 2018, Muramatsu returned to Keio University and was appointed as a senior assistant professor in the Department of Mechanical Engineering. She assumed her current position as an Associate Professor as of April 2022.

The Research

Associate Professor Mayu Muramatsu discusses how she hopes to make breakthroughs in monozukuri manufacturing by combining various methodologies and models with numerical simulations that use the finite element method.

Contributing to Monozukuri Manufacturing through Numerical Simulations

An extensive field of study that encompasses prosthetic limb defect detection, apps that recommend metallographic structures, quantum computing, and more

Muramatsu is blazing new trails as she works to expand the capabilities and possibilities of numerical simulations, combining them with other methodologies and thinking how to implement them in quantum computing. In our interview, we asked her about the unique results she has achieved on her journey, such as her technology for detecting defects in prosthetic limbs, developing an app to recommend metallographic structures, and proposing methods that bridge different types of numerical simulations.

Using the “Finite Element Method” to Investigate How Objects Deform

How much load can an airplane wing withstand? How do the bodies of cars crumple upon collision? How do we know if there are any foreign substances mixed into the materials of a prosthetic limb? In order to live our lives safely, there are myriad things we need to know about manufacturing materials. However, conducting real experiments can be prohibitive both in terms of time and cost. In these situations, “numerical simulations” can be incredibly powerful tools. They are computer renderings of experiments that use numerical models (equations) to express targeted physical phenomena.

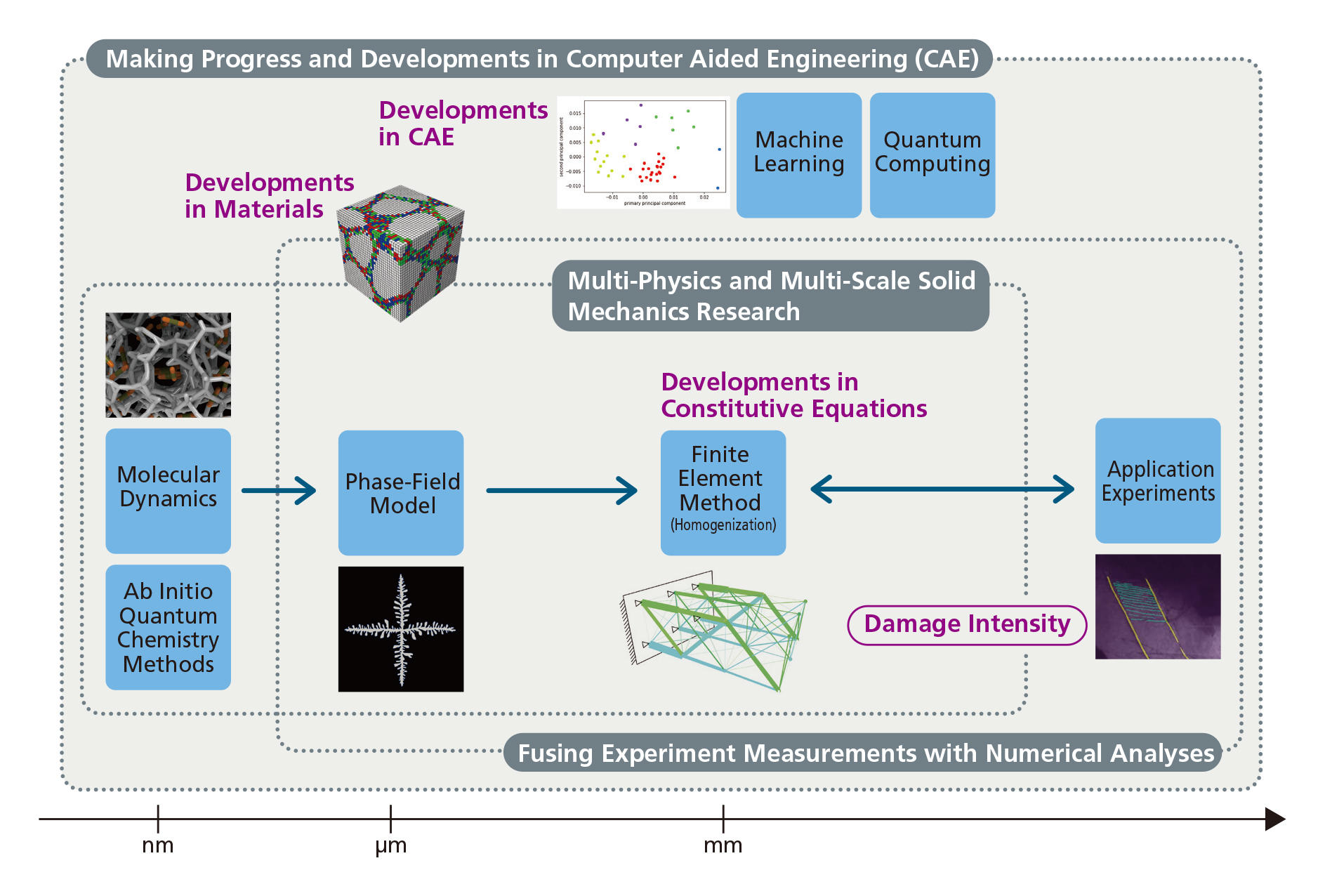

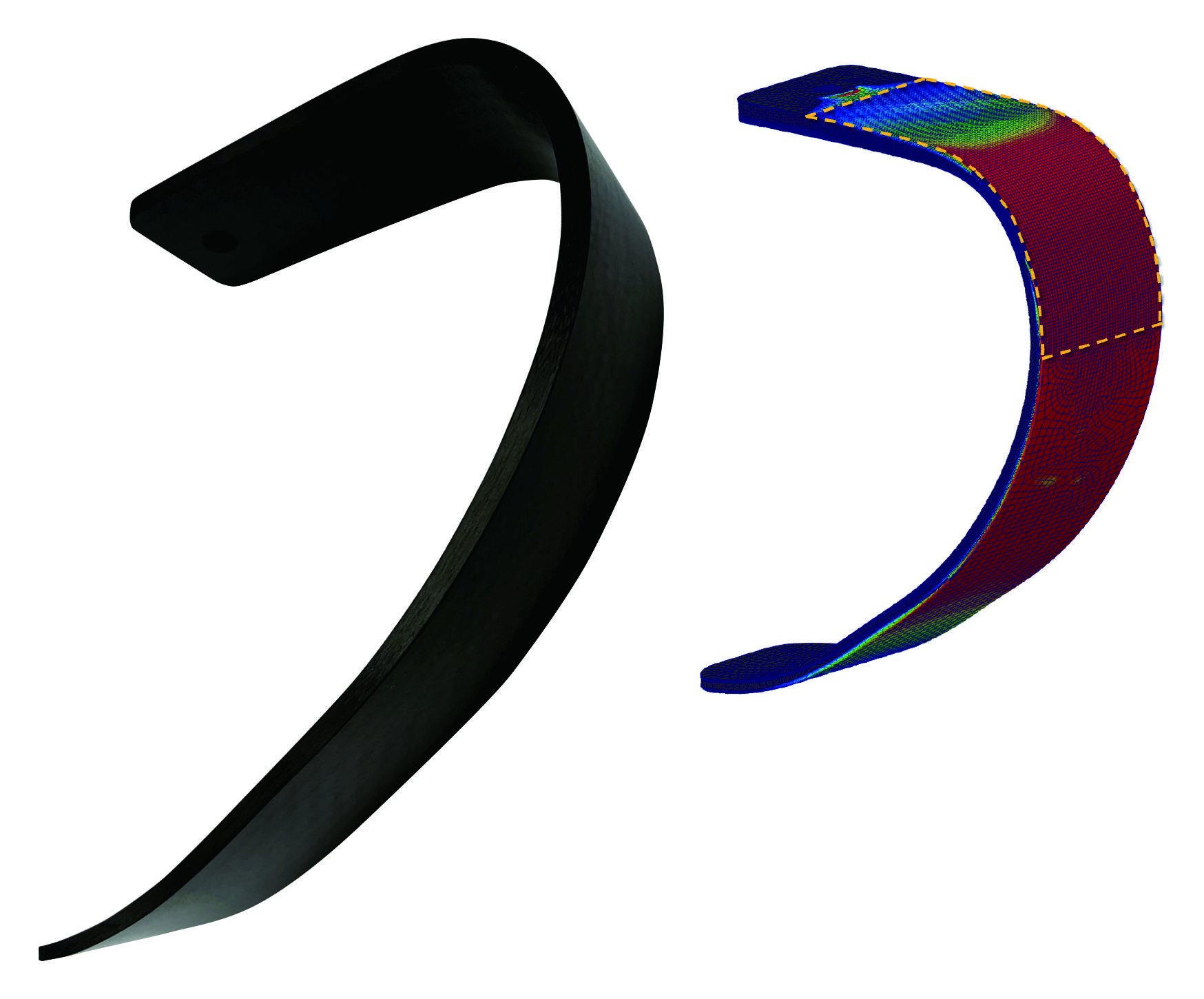

The methodology changes with scale, but for Muramatsu’s work with materials that are used to build airplanes and other vehicles, the main approach is to use the “finite element method (FEM)” which can handle phenomena ranging from millimeters to kilometers in size (Figure 1). FEM divides the target materials into smaller polygons (see front cover), solves for the equations of motions for those individual pieces, and integrates this information to analyze how the object as a whole will react or deform. FEM is already being used to design structures such as roads and buildings.

When asked about her research, Muramatsu said, “I would say that the finite element method is the main theme of my research, but I want to be able to analyze materials in greater detail, so I am working to combine a variety of methodologies together.” Diving from one outside academic field to the next, Muramatsu is intent upon improving numerical simulations, taking the field to new heights by using these simulations to develop materials.

The simulations listed are as follows: Molecular dynamics: method for analyzing the physical movements of atoms and molecules; Ab initio quantum chemistry: method which only uses experimental values of fundamental physical constants; Phase-field model: method to calculate crystal growth; FEM: method to work with complex shapes or materials.

I Want to Find Defects in Prosthetic Limbs

Using machine learning, FEM, and application experiments

Muramatsu’s lab is currently developing an application that can detect defects in prosthetic limbs. The technology combines FEM with machine learning (a type of AI) and application experiments.

Prosthetic limbs are made of an incredibly strong and light material known as carbon fiber reinforced plastic (CFRP). CFRP is also used in airplane wings and motorcycle bodies, but because it is created by overlapping multiple sheets of carbon fiber cloth, foreign substances may be inadvertently introduced to the material and affect its strength. This means that for quality assurance and user safety, two people have to conduct a full ultrasound inspection on the completed product where it is assembled. Muramatsu’s goal is to reduce time and labor by replacing one of these technicians with an AI.

“When you apply force to a material and make it deform, they have a property that makes them release heat. This means that it is possible to capture a force distribution on a material by using a thermal camera. My idea was that it would be possible to use AI to determine where foreign matter had gotten mixed into the material based on whether irregularities appeared in the temperature distribution.”

To make this technology into a reality, it is necessary to train the AI with immense amounts of data showing foreign matter being introduced to a material and the corresponding temperatures when this happens. However, since CFRP is an expensive material, it is not possible to actually put together enough experiments that can show data for all of the relevant types of contaminants. This is where numerical simulation comes into play. Based on a limited amount of real experimental data, a computer can postulate other scenarios in which other contaminants are present. This is the basic idea that formed the application which can assess whether foreign objects are present in a prosthetic leg (Figure 2).

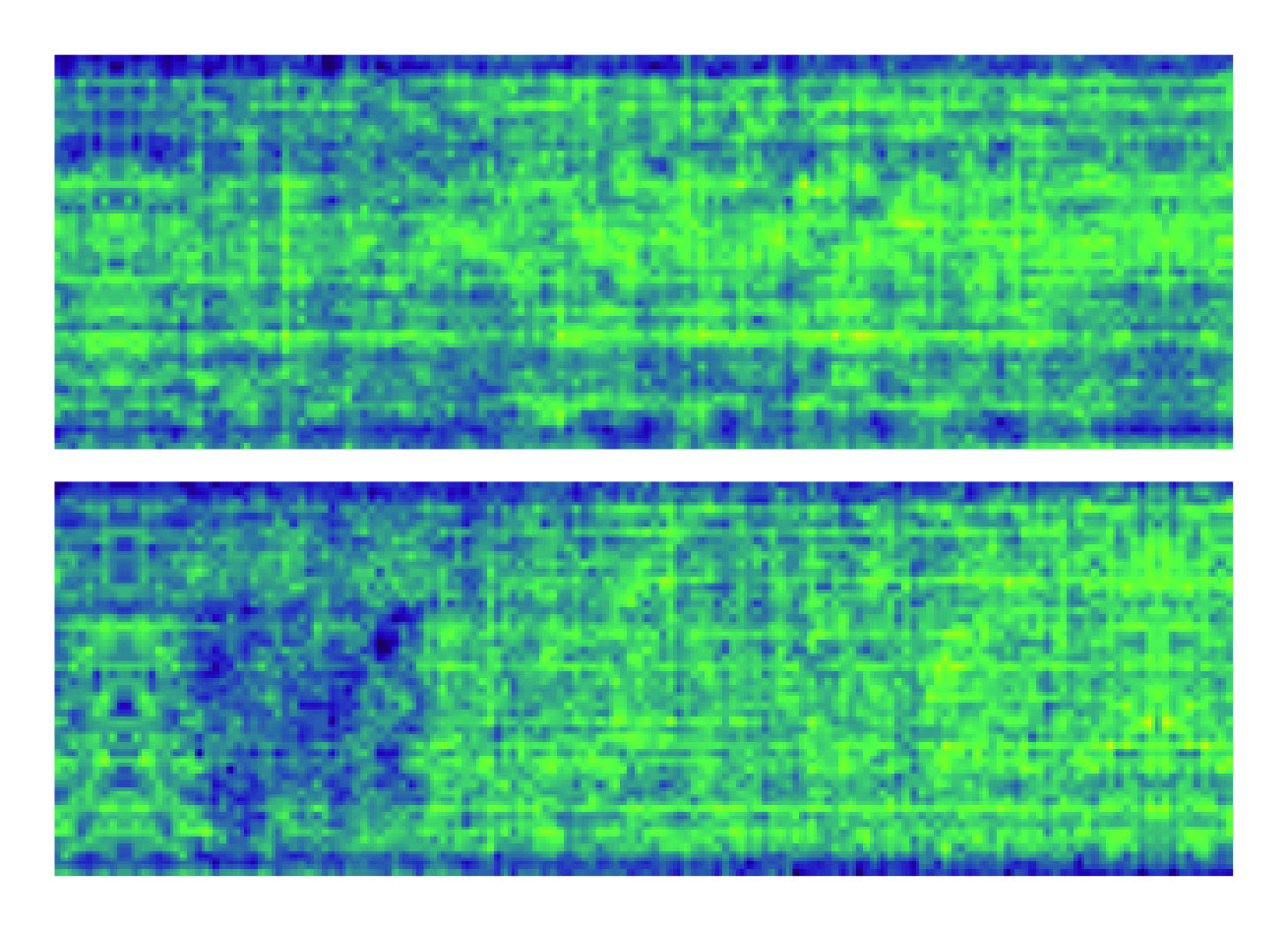

Figure 2: A prosthetic leg (left) and how it compresses (middle) as well as thermal images showing difference between material with and without foreign contaminants (right) The dark blue patch in the left portion of the bottom image depicts a square foreign substance. There are no foreign substances in the top image.

I Want to Know Which Structures Determine a Material’s Properties

Using machine learning, FEM, and phase-field modeling

“A material’s internal microstructure (how it separates) determines its strength, workability, and the way it will deform. This means there is a great need to identify the patterns of potential structures for different materials. You also will want to know how the material deforms when force is applied to this structure.” This type of calculation can be done using conventional numerical simulations, but it is very time consuming. Muramatsu, thinking that the current approach was useless for actually trying to develop new materials, solved this problem by using machine learning two times over.

“The first round of machine learning looks at patterns in the material’s structure. The second round of machine learning predicts how strong the material is, looking at how much the material can stretch and how well it absorbs applied force. The program then recommends structural patterns with the desired characteristics.”

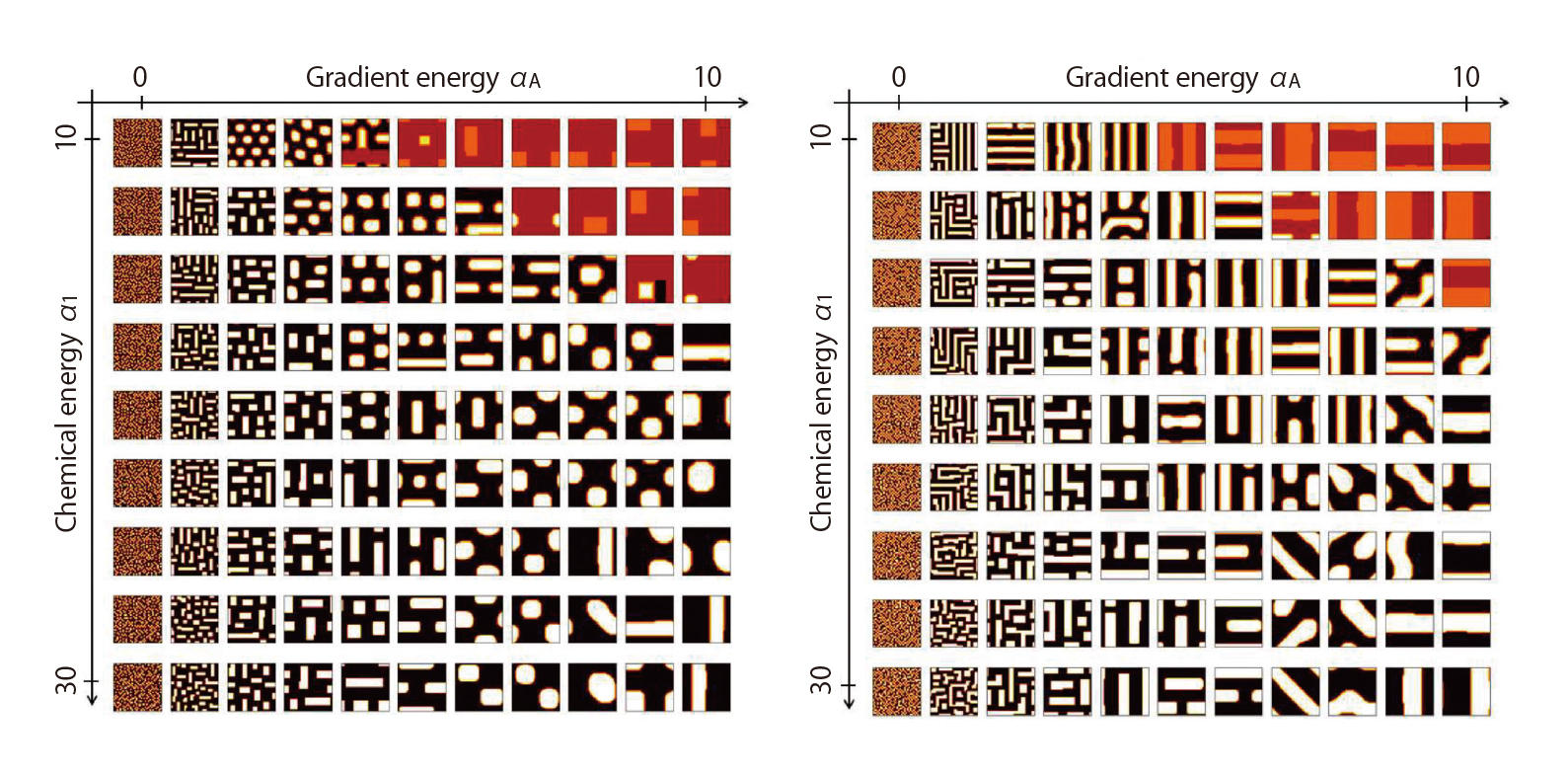

Figure 3: Patterns of material structures derived from quantum computers Calculations of two different types of materials showing their structures (how they separate). Moving right shows when conditions allow for the materials to mix more easily due to higher temperatures, etc. Moving down shows when the materials are least likely to mix due to their different properties. The right image shows a ratio of 7:3 while the left image shows a ratio of 6:4.

New Developments in Numerical Simulation

Both the technology to find defects in prosthetic legs and the technology to recommend material structures were created from the desire to apply data obtained from numerical simulations to monozukuri manufacturing.

Muramatsu’s research, however, extends far beyond even these accomplishments. One such example is her goal of combining molecular dynamics with FEM. “When analyzing a material with FEM, you designate whether it is a metal, a plastic, or a ceramic. Different materials have different properties that require specialized constitutive equations to solve. This means that it is impossible to analyze new materials for which there are no known constitutive equations. However, constitutive equations are derived using molecular dynamic simulations which show movement on the molecular scale. I realized that if that was the case, why not just combine molecular dynamics directly with FEM?” Muramatsu’s daring idea to bypass constitutive equations by combining different scales of simulations has already met with some success. Furthermore, Muramatsu is working on developing an application that can run numerical simulations on what is regarded as the next generation of computing technology: quantum computers. Quantum computers use quantum mechanics and, because they function in a fundamentally different way than the traditional type of computers we use now, it is necessary to develop new applications to run on this type of system.

Muramatsu says that this is the type of challenge she is able to take on because she works at Keio University.

“First of all, President Kohei Itoh himself is a quantum computer research scientist. We also have an incredibly vigorous quantum computing program, with Keio University establishing the IBM Q Network Hub in 2018, becoming the only organization in Asia to have access to IBM’s latest model of quantum computer from the United States (As covered in Issue No. 29 of the new Kyurizukai). I wondered whether it would be possible to use this technology for computational mechanics as well.”

Even when working with low-resolution input, quantum computers can calculate a pattern of a structure that is a blend of various materials in only a single second. This type of computer can put out a low-resolution pattern of a structure made up of a blend of materials in only a single second. Previous attempts on traditional computers would take approximately twenty minutes, making this a huge step forward. Researchers are just waiting for quantum computers to become more precise and practical (Figure 3).

Muramatsu’s research ranges from so many different areas and subjects that it cannot be covered in just one article. It is hard to take our eyes off Muramatsu and her work, and impossible to guess what she might embark on next.

Interview

The Interview: Associate Professor Mayu Muramatsu

Discovering an interest in math and science during a high school physics class

Did you like math and science when you were a kid?

Not at all. I studied math and science so that I could pass the regular tests, but I didn’t like them particularly more than other subjects. In fact, my real interest was reading. In elementary school, while all the other students were playing dodgeball and other games, I was often holed up by myself in the library. I still love reading even now. Whenever something is worrying me, I turn to books to look for an answer. If anyone out there has had their heart broken, I even have books I can recommend for that [laughs].

The catalyst which sparked my interest in math and science was my high school physics class. Some people reading this may remember an experiment where you learn how the heavier an object is, the closer it will land when thrown, whereas lighter objects will travel farther. While this might seem obvious, I found it beautiful that you could express this phenomenon using mathematical formulae and the laws of physics. I wanted to know more about who had come up with these laws. This was when I decided to major in mechanical engineering for college.

You graduated from Keio University’s Faculty of Science and Technology, right?

That’s right. My parents and two younger sisters were liberal arts majors, but my grandfather had conducted research about soy sauce and other topics in agricultural science, so sometimes he would teach me about chemistry and biology. Even though I told him that I only wanted to learn things that would show up on tests, he was sure to tell me things that wouldn’t ever be included [laughs]. I remember how much I respected him for knowing so much about so many different topics. My grandfather was very happy for me when I was able to enroll at Keio University’s Faculty of Science and Technology.

I think that the draw of physics and mechanics is that you can feel its impact in your daily life, like when you observe how much an airplane wing flexes when force is applied to it. Taking that to the digital realm, you can use formulae and computer simulations to create accurate representations of real physical phenomena. I wanted to keep learning more advanced mechanics, and so this led me to pursuing a career in research after I graduated.

Life in the countryside; Sendai becomes a second home.

After graduation, I understand that you gained experience working for a research institute and as a faculty member for a university.

After graduating from Keio, I spent two years at the National Institute of Advanced Industrial Science and Technology in Tsukuba. I then spent four years in Sendai Prefecture working at Tohoku University. I decided to work for AIST because I did not think of myself as the “teacher type,” but when I actually started working there it was very lonely and I felt isolated. I realized that I didn’t belong in a place where there were no students. As in research institutes you are primarily required to make progress on your own research projects, I didn’t have a chance to study with my colleagues either.

That was when Dr. Kenjiro Terada from Tohoku University invited me to work there as a postdoctoral researcher. For someone who had always lived in the Kanto region of Japan, moving up north to Tohoku felt like a complete reset, so it took a lot of resolution to make that decision. However, when I went there, I found it to be a wonderful environment for working on my research. I was given free rein to conduct my numerical simulations and I enjoyed interacting with the students. I also spent plenty of time talking with Dr. Terada. He influenced me quite a bit. Over time, Sendai became my second home.

Are there significant differences between a research institute and a university?

While my main area of focus is numerical simulations, at AIST I was told to do some experiments using thermal cameras. I was completely ignorant of the research going on in that field, so it took an incredible amount of work before I was familiar enough with the subject matter to find a relevant topic that would work for an academic paper and produce results. Under the system in place at the time, if you didn’t fulfill a certain quota of papers within a given timeframe, you wouldn’t be able to stay at AIST, so I was desperate. On the positive side, since things were the way they were, by the time I decided to move to Tohoku University, I had already amassed a decent portfolio of work.

Back then, I was so anxious about my future and eager to become an indispensable researcher fast in a specific area. But thanks to the experiences and ideas I gained during my time at AIST, now I am able to carry out a wide array of research projects. In fact, I am still being allowed to experiment with prosthetic legs and other devices at AIST, and I have continued my thermal camera research.

Teaching at her alma mater, Muramatsu invests in the next generation and in a new business venture

Tell us about what it was like coming back to Keio University, your alma mater, in 2018.

The biggest change for me was being put in charge of a laboratory. Up until then, I had never been in a position where I had to speak in front of groups or take on leadership roles. I found the transition to be very difficult, so I read books written by sports coaches. If the “goal” of research is to publish academic papers, then both sports and laboratories are team-based games. Likewise, they both share aspects which are highly individual. Every person on the team needs to be able to express their own abilities and personalities. I think the two worlds are similar in that respect, too.

How can I help students who share my research interests hone their individual skills and how can I help each one of them “brand” themselves to succeed when venturing out into the world? I especially feel this with students who will be going on to do a Ph.D. program because they will become lifelong research colleagues. I want to lay a foundation and pave a path forward for them to thrive in research communities based on their own capabilities.

I feel this way because I truly enjoy my research in computational mechanics and think highly of the field. 300 years from now most people, no matter which path they choose, will be forgotten. I am no exception. My hope is just that I can connect with my students so that they share the same ambition that I have; to advance this field and bring it into the future.

Your students must be thrilled to have a teacher who cares so much about them.

I was reading a book called Mathematicians and the French Revolution which lists influential mathematicians from about 250 years ago and while there were some famous examples that anyone would recognize, there were also names that I had never seen before in my life. Even people who are considered famous in their own time are forgotten after two or three hundred years. That applies to you, me, and everyone. When I realized this, I thought that it was more important to focus on passing the baton forward to future generations rather than just trying to bolster my personal accomplishments. The act of passing on knowledge itself will be my legacy. Both “life” and “research” have extensive histories. Because of this, I have started at looking at things from a wider perspective and I believe that it’s important to think about ways that we can contribute to them

Another factor is the inspiration I draw from my students. For example, through them, I am often reminded of the things that I once found difficult to understand. It’s a privilege to be given the chance to accumulate diverse experiences and opportunities to think and rethink on what I’ve learned. Likewise, I often hit upon a new idea through conversations with my students.

I also understand that you’re quite the entrepreneur?

While my research never seemed to cross paths with the world of business or entrepreneurship, I have always felt that it is important to be able to implement research findings in society for it to be useful. As I was thinking about this issue, one of my students recommended an entrepreneurship seminar that the graduate school was offering, and I signed up. Keio students are incredibly independent and, in the best way possible, don’t mindlessly listen to what people tell them to do. Instead, I have noticed that they will zero in on and get involved in projects that they genuinely believe in and which align with their personal interests. I know students who bring in their own original ideas to incorporate to our research projects as well as those who want to work on and go into business with the prosthetic limb defect detection technology that I mentioned in my research overview. I think that successful people have an instinctive ability to get the timing right. This ability can also be acquired, possibly by meeting up with many people. In both entrepreneurship and research, you should do what you need on a daily basis in preparation for the future, while trying to take as many opportunities as you can to meet up with other people. I sincerely hope that my students will make the most of the precious time they have in college.

I learned that it was important to get feedback and have discussions with customers when putting the finishing touches on products, and that this process can help guide the timeline for a startup. It was useful to learn about various approaches to entrepreneurship, but I especially enjoyed hearing from people who themselves possessed the mindset of an entrepreneur.

Some words from Students…

I have always been interested in "modeling" as a way to simplify the complexities of society. In class, I learned that you can “model” materials and I thought it sounded interesting. When I was deciding which laboratory to join, I told Professor Muramatsu that I was interested in continuing my studies in sociology. Her response was to say that research is fueled by a wealth of experiences, and that was the decisive factor for me in choosing to join the lab. Once the COVID-19 pandemic started to get under control, I was able to meet a lot of different people at the university. I’ve learned that the world is much wider than I had ever imagined back in high school. Professor Muramatsu is the one always showing me new research and daily happenings that help broaden my horizons. (4th-year undergraduate student)

(Interview and transcription: Akiko Ikeda)